The Industrial IoT for Predictive Maintenance: A Game-Changer

If you are a manufacturer or if you are managing a large install base of equipment, maintaining the equipment optimally is a challenge. You are also likely to take the following approach to maintenance:

- Calendar-Based Maintenance: Periodically examining and fixing problems based on a fixed schedule

- Reactive Maintenance: Waiting for things to fail and then fix the problem

- Given today’s competitive landscape, manufacturers and asset managers are looking for a better approach:

- Can I detect equipment failures before they happen, and fix them?

- Can I get field data from the equipment and use that in R&D to build a better product?

- Can I offer value added services to my customers on top of hardware? For instance, guaranteed equipment uptime for a monthly fee.

All these concerns can be effectively addressed by integrating Internet of Things (IoT) with your current equipment. IoT is the biggest enabler of condition based monitoring of industrial equipment, a prerequisite for predictive maintenance. This article will cover this in detail.

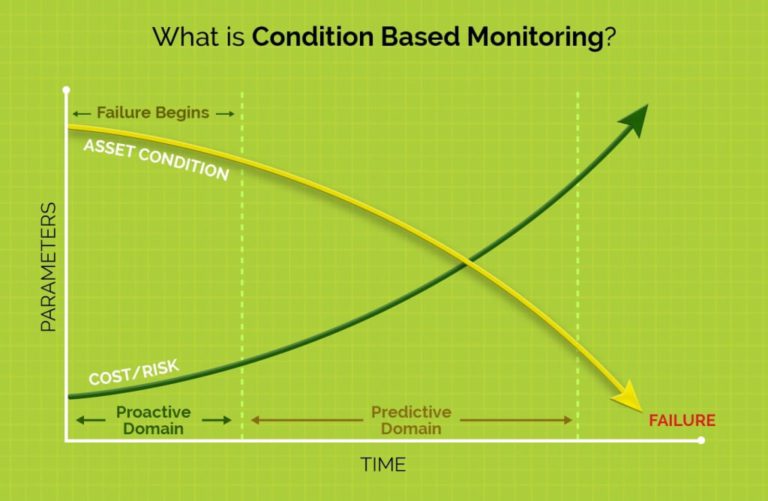

What is Condition Based Monitoring?

What is Condition Monitoring?

Condition Based Monitoring is a process by which the condition of a machine is continuously monitored by looking at pre-defined parameters of the equipment. Doing so enables the tracking of patterns that might indicate equipment failure. Early failure prediction allows for timely action and prevents a major failure down the line. This ensures longevity and smooth running of the equipment. Condition monitoring is a critical aspect of preventive maintenance; it ensures that equipment is always running or being maintained in a predictable fashion by flagging variance in parameters being monitored. Condition monitoring also allows you to know when your equipment is nearing the end of its life. This allows for the operations team to plan for its gradual replacement.

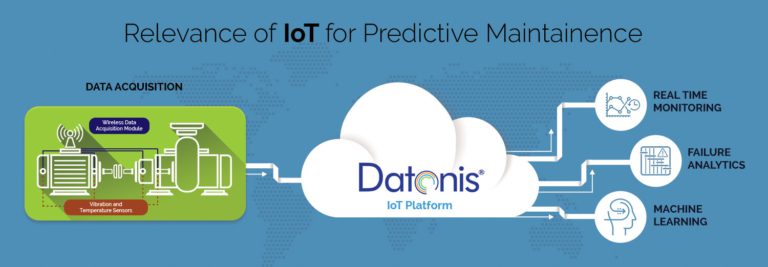

The Relevance of IoT for Predictive Maintenance

IoT for Predictive Maintenance Project Implementation using Datonis – From Data Acquisition to Advanced Data Analytics (Machine Learning, Real-Time Monitoring and Failure Analytics)

The Internet of Things (IoT) is the outcome of technology advances in four main areas:

- Connected Devices and Sensors: Manufacturers are building sophisticated, connected gateway products. These products provide standardized ways to talk to the world of sensors.

- Ubiquitous Data Networks: Telecom companies are building better and cheaper data networks with widespread coverage.

- Rise of the Cloud: The rise of the cloud is leading to the big shift from enterprise to Software as a Service (SaaS) platforms.

- Big-Data Technology: The ability to process large amounts of data in a standardized way can be a boon to companies looking at assessing their processes in a detailed manner.

This means that every ‘thing’ around you can connect and communicate its status back to software platforms. Cloud based software platforms built on latest advances in big data technology can swiftly process this information and offer insights, a direct prerequisite for predictive maintenance.

So I’ve connected my Machine. What Next?

Once your equipment is connected, you need to start analyzing its parameters for failure. Here are some of the parameters that are commonly monitored and analyzed:

- Vibration: Monitoring the vibration of equipment, usually bearing vibration

- Temperature: Monitoring the temperature variation

- Oil Levels: Measuring the variation in oil levels of equipment

- Acoustics: Using ultrasound to detect changes in sound made by the equipment

- Motor Voltage and Current: Monitoring for nuisance corona, destructive corona, arcing and tracking

Once your failure parameters are finalized, you would need to establish a failure model for the equipment. This model must be able to distinguish between a normal state and an abnormal state that is a leading indicator of failure.

Building the Right Failure Model

You are faced with the following choices, once the right parameters are available for analysis

- I know what combination of parameter values is indicative of failure. This form of analysis relies on human intelligence and is far simpler to implement. You need the ability to specify a set of rules or failure conditions. If these are violated, the machine is likely to fail.

- I have no idea what causes failure. I need data science and machine learning to figure this out for me. This form of analysis involves using the right algorithms to see patterns in your data.

In most cases, you do know the reasons for failure. You can use classical data analytics and mathematics to build the right model. Machine learning is used in those rare instances where you have no known parameter that is indicative of failure, or if the patterns that cause failure are too complex to discern by standard data analysis.

Machine Learning

You can rely on machine learning if you cannot define a failure model for your equipment using classical data analytics. Machine learning algorithms are classified into two broad categories.

- Unsupervised Learning: This involves algorithms that run on a data set with no human intervention. The result is a set of automatically identified patterns from your data that can be mapped to equipment failure.

- Supervised Analysis: These are algorithms that you train to detect the failure. You give it a subset of the data, which is already classified as a failure/not a failure. The algorithm learns from that and can then be run on the complete data to pick out equipment failure.

You need to have a good understanding of data science before you try machine learning. You will also need to find the combination of algorithms and their configurations to make it work for you. You should also look out for model entropy. Machine learning models need to be constantly monitored for their effectiveness. Models often degrade with time and need reconfiguration or retraining.

Monetizing Predictive Maintenance

Having real field data helps you predict failure and build a better product. It can also impact your top-line. Manufacturers and service providers are looking beyond selling hardware – they are also looking at selling value-added services which guarantee recurring revenue. Predictive maintenance and condition based monitoring directly impact equipment uptime. By offering predictive maintenance as a service, the manufacturer can now offer equipment uptime guarantee to their customers for a fee. The customer is usually happy to sign up as this brings predictability to their business. Everyone wins. And with autonomous maintenance, early equipment failure detection, preventive replacement and condition monitoring, these CMMS (Computerized Maintenance Management Systems) software facilitate TPM Implementation (Total Productive Maintenance) in real time.

How can Altizon Help?

This article has hopefully given you a perspective on how IoT is relevant to your business and can be your stepping stone to Industry 4.0. Get started by connecting a couple of your assembly lines to a modern IoT platform and seeing how machine data analytics can really impact your business. Click here to create a free account for Datonis and experience the power of IoT for your devices.

Altizon is focused on helping you get started with the Industrial Internet of Things and Industry 4.0. We provide adapters to connect existing hardware, SCADA, DCS and Enterprise Data Historians. Altizon’s Datonis platform is a highly scalable, cloud-based IoT platform that allows devices to securely connect and exchange information in real-time.

Manufacturers are increasingly adopting industrial IoT platforms to transform their enterprise into a smart factory with scalable technology. Let Altizon connect one of your key processes within 4 weeks and uncover opportunities for payback.