How a Global CPG Company Improved Production Line Efficiency by 8% Using Datonis IoT Solution

How a Global CPG Leader Improved Production Line Efficiency by 8% Using Datonis IoT Solution

CPG Case Study

Read Our Case Study

Sector

CPG Line Monitoring

Customer Profile

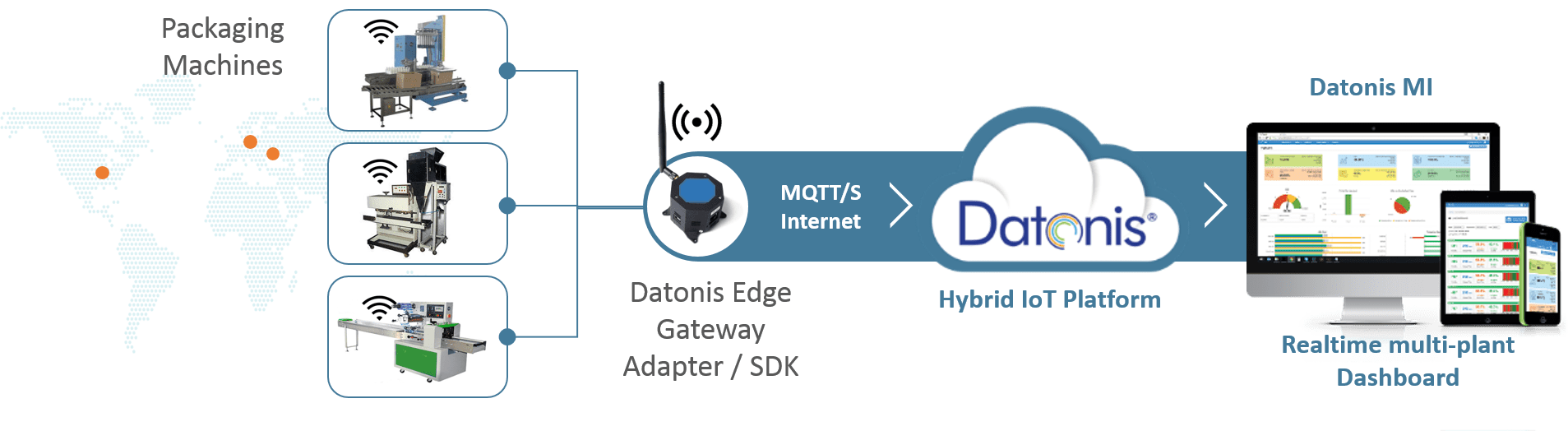

A Global CPG leader implements integrated smart IoT solution to analyze the efficiency of packaging lines at warehouses in multiple countries.

The Challenge

The leading CPG company operates several warehouses, mostly closer to the last distribution point (Large retailers). Products in various categories are packaged in specific delivery or display cartons at these facilities. As most CPG businesses consist of high volume with low margins, optimizing every operation and effective utilization of resources add up to profit margins. The key problem at these warehouses is the lack of visibility into reasons for machine breakdowns or idle time, thereby delay in delivery. The sunrise meetings lead to post-mortem of delivery issues like delay or quality. Customer wanted to implement realtime line monitoring and alert system to gain control over downtime issues and implement improvement measures.

Solution

As packaging lines carry variety of old and new machines, many aren’t designed to share data. The solution demanded retrofitting of hardware and custom dashboards to visualize multiple lines and machines. Altizon, along with the hardware partner, designed an integrated IoT solution. It deployed high quality wireless object detection sensors on case sealers, wrapping machines, and box printers to capture real-time operating pulse. The 24/7 real-time machine data at Datonis Edge helped analyze equipment failure & generate alerts. The aggregated data was processed at Datonis IoT cloud to analyze production line throughput and offer tailored visualization and BI reports. The business intelligence reports with machine idle time, breakdown reason codes, and overall productivity/OEE data helped management in better planning and addressing issues..

Benefits/Outcomes

- Retrofitting the Hardware: For the older machines which could not send data, a simple wireless and battery-operated sensor mechanism was implemented. In other cases, data was tapped from existing SCADA, DCS systems. Therefore, the solution required no hardware changes to existing packing line system.

- Faster Deployment: Overall deployment time is in minutes and not in days. Because of Datonis IoT platform’s wide range of connectivity protocols and ‘Thing’ templates, overall deployment time was in minutes and not in days. With platform features, data aggregation, processing, and reporting started immediately, and the solution came in operation instantly.

- Easy Customization: With extended APIs and easy SDK, application customization is smooth. In addition to the canned reports, the DIY reporting capabilities help users to slice and dice data as needed and build custom reports to get additional actionable insights.

- Scalability: With one site implementation, the solution framework and Datonis platform’s enterprise grade scalability enabled to expand the solution to 2 more plants in less than 6 months.

Realized Benefits:

- Real-time visibility into packaging line’s performance (downtime sources, suboptimal processes, slow teams, aging equipment)

- Up to 8% performance gain through optimization initiatives driven by actionable insights

Read Our Case Study

Steel Case Study

Leading Global Metal Forging Company Lays The Foundation Of Industry 4.0 Using Altizon’s IoT Platform.

Energy Case Study

Monitoring Power Availability and Quality Across India Using Datonis®