Skip the multi-year implementation cycles. Our standardized framework delivers measurable operational impact in weeks, not months.

Define strategy: Identify high-impact lines and specific data points for the initial rollout.

Establish links: Securely connect to machines, automation systems, and key legacy processes.

Unify data: Remotely connect and normalize raw machine data into a single "Source of Truth."

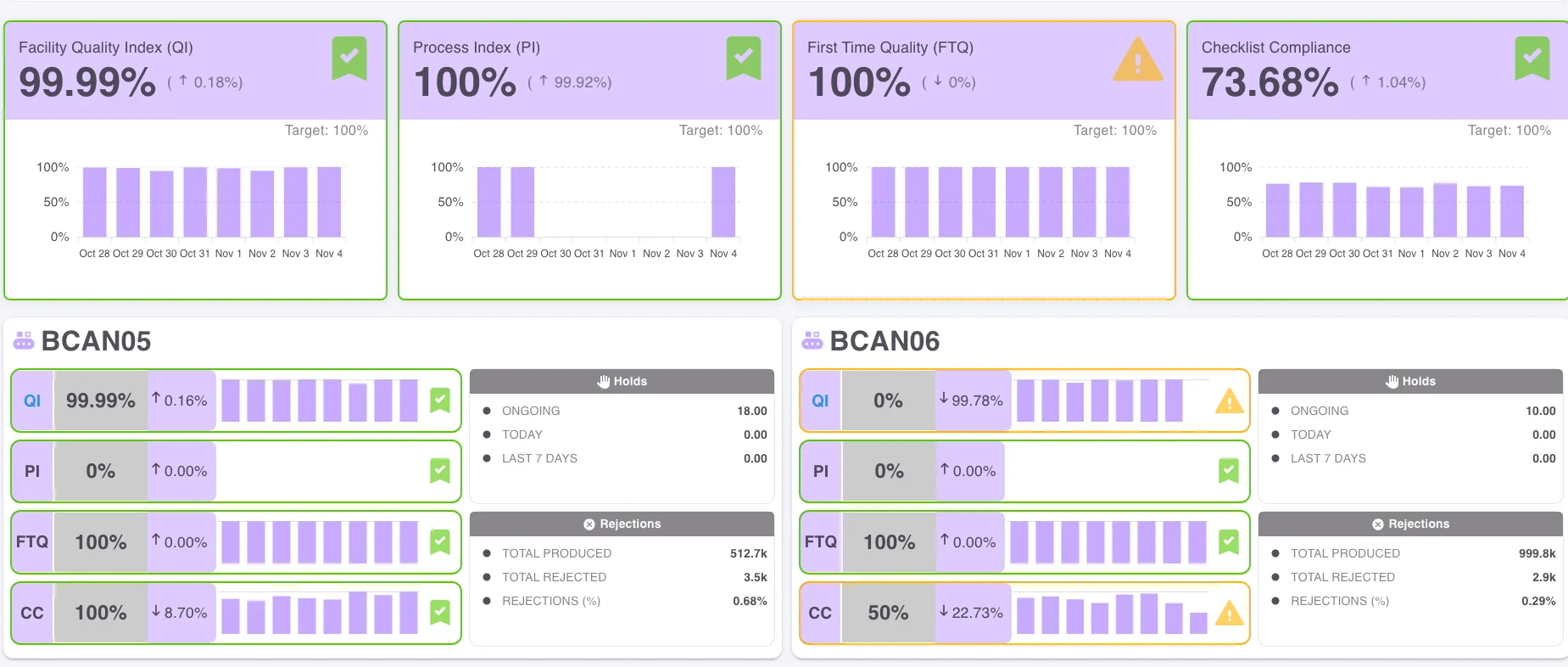

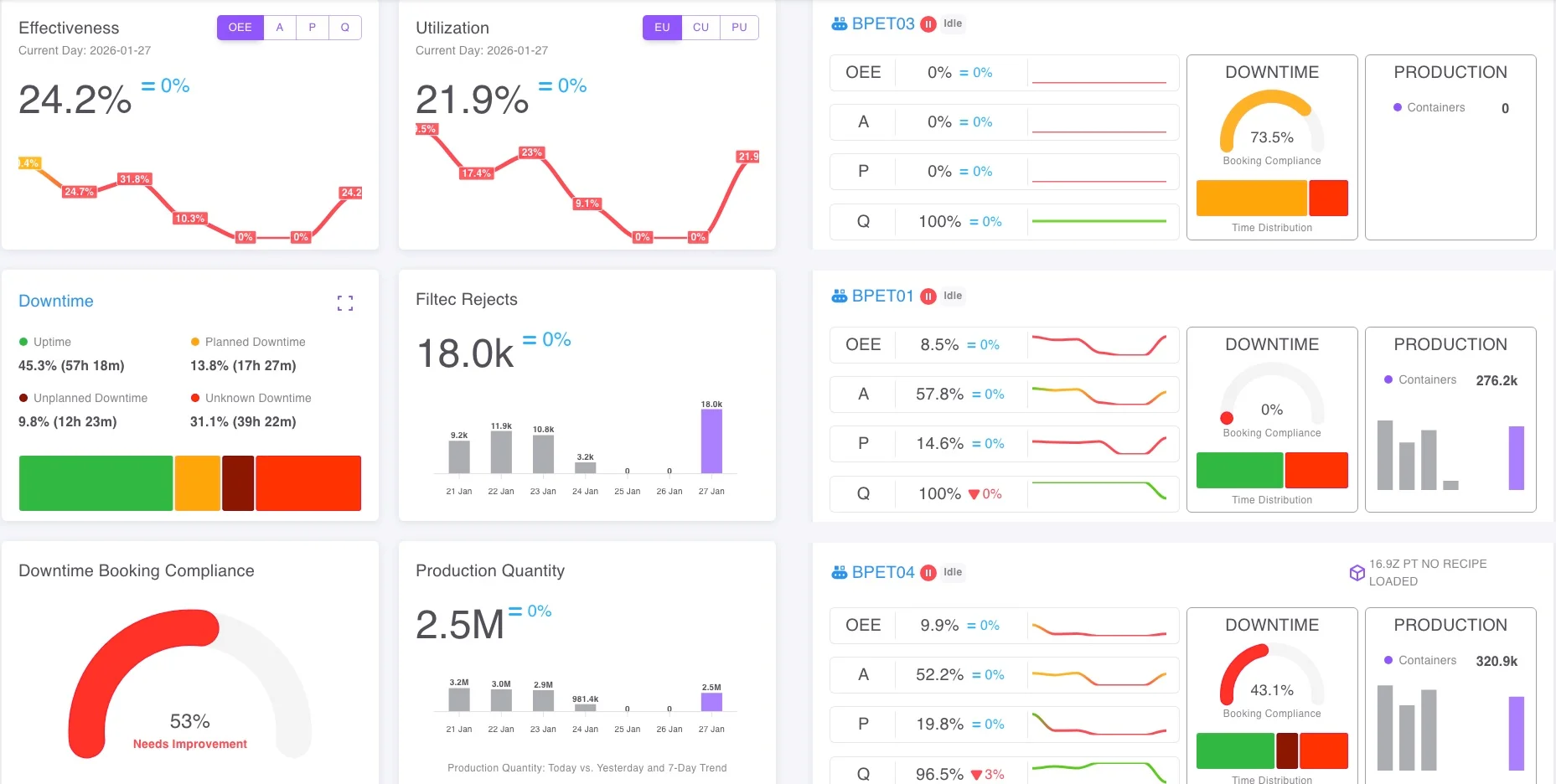

Map KPIs: Align data streams to core performance metrics like OEE, cycle time, and availability.

Enable personas: Activate specific suites (Performance, Quality, or Sustainability) for targeted user roles.

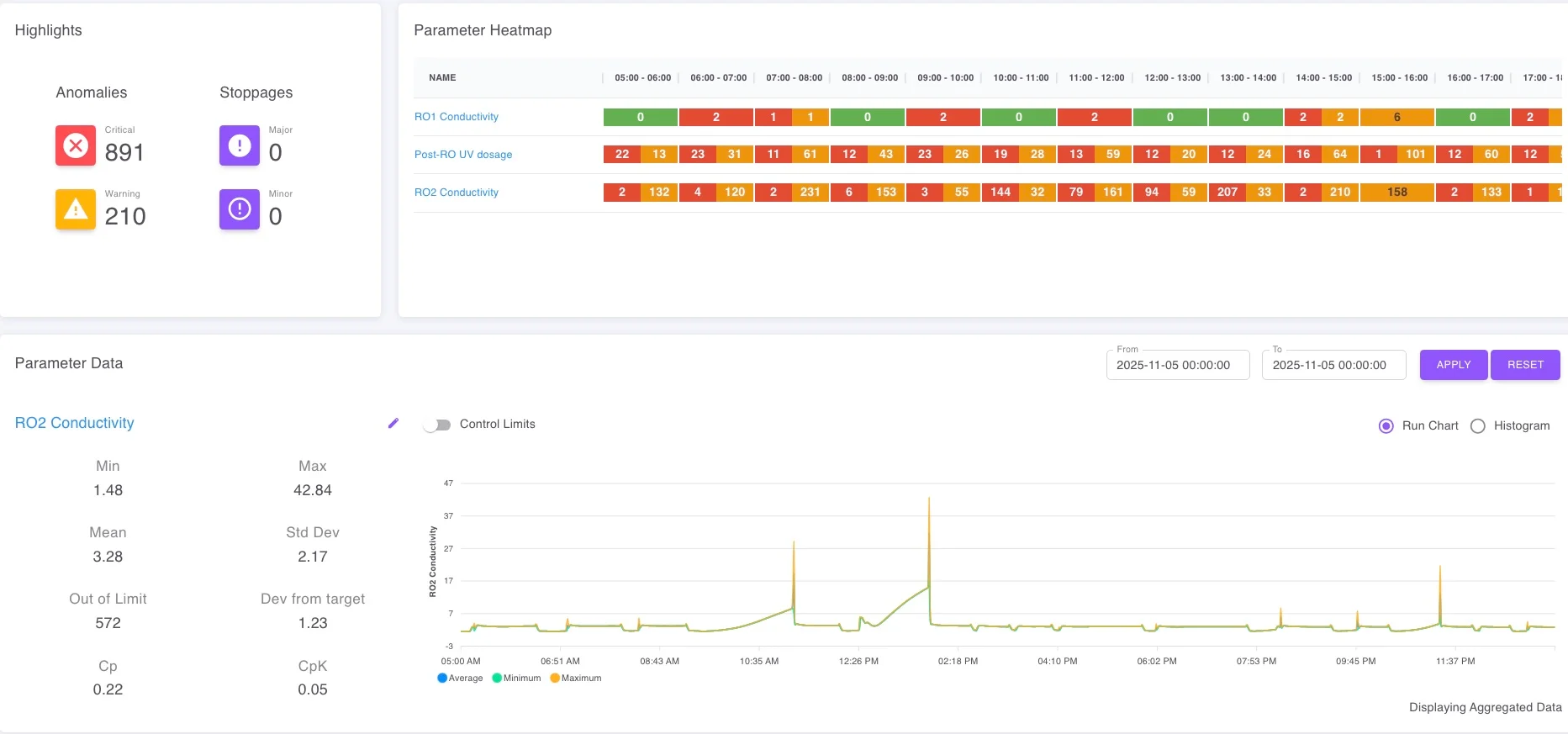

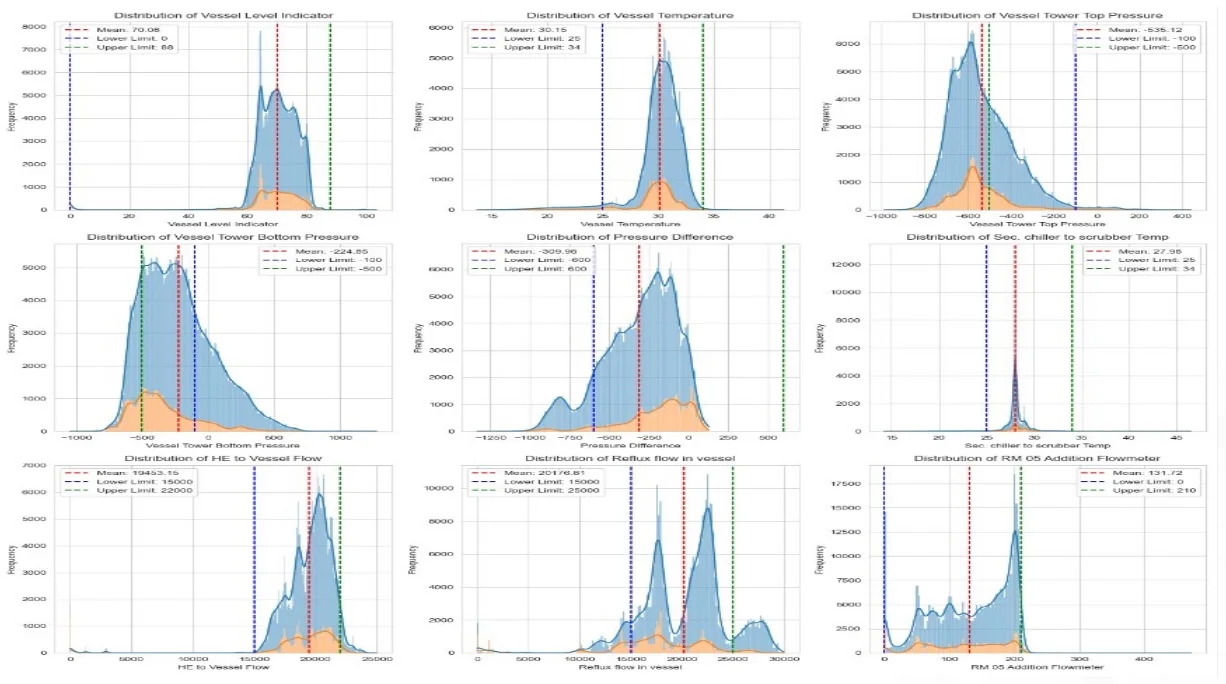

Baseline performance: Begin real-time monitoring to capture baseline data and identify immediate outliers.

Uncover potential: Dramatically improve KPIs by identifying hidden downtime and process deviations through live analysis.

Empower teams: Equip operations and IT with DFX Apps and BI for data-driven decision making and self-service analytics.

Anticipate outcomes: Transition from reactive monitoring to predictive modeling for quality and maintenance.

Natural interaction: Deploy Generative AI agents to interact with operational data using natural language.

Global scale: Benchmark performance across the entire footprint and replicate "Golden Site" configurations

A cloud-native architecture designed to meet the most stringent scalability and security standards.

End-to-end encryption: Protect data at rest and in transit with AES-256 encryption and secure TLS protocols.

Compliance certified: Built on a foundation that aligns with SOC2 to ensure total data integrity.

Edge-to-cloud connectivity: Securely bridge the gap between OT (Operational Technology) and IT using industry-standard protocols like MQTT, OPC-UA, and HTTPS.

Bi-directional ERP sync: Out-of-the-box connectors for SAP, Oracle, and Microsoft Dynamics to ensure production data is always in sync with business systems.

Cloud-native scalability: Built on a microservices architecture that scales horizontally across lines, plants, and geographies without performance degradation.

Hybrid deployment flexiblity: Deploy on your preferred cloud provider and utilize edge computing for low-latency requirements.

Enterprise SSO: Integrate with Azure AD, Okta, or other SAML/OAuth providers for centralized user management.

Granular RBAC: Role-Based Access Control (RBAC) ensures that the right people have access to the right data—from the shop floor to the C-suite.