IoT Enabled Digital Transformation in CPG

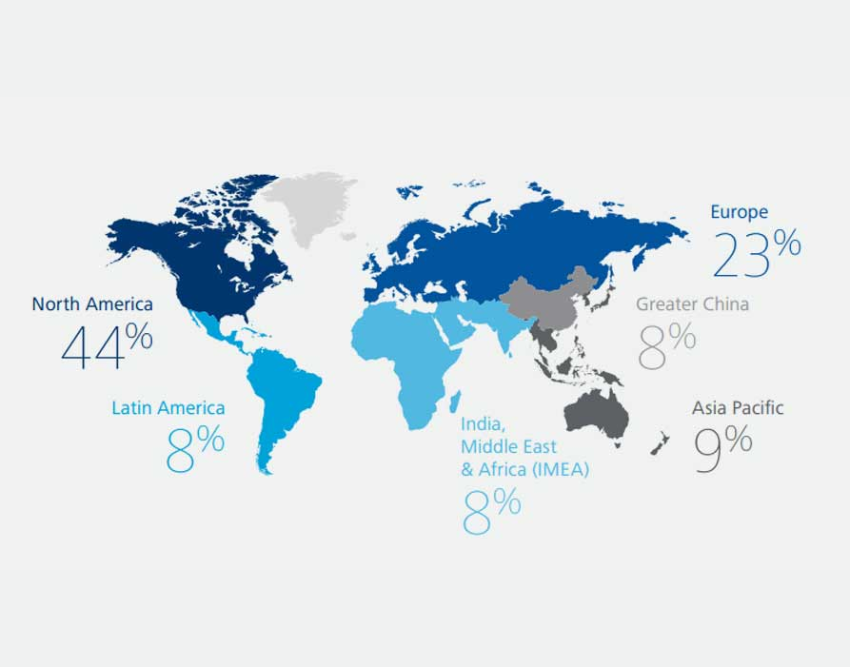

The Customer

The Problem

- A complex, wireless sensor-based tracking of line performance, along with plug-and-play sensors and hardware with minimal installation overhead

- A cloud-based, multi-tenant hosted platform as the single data repository for plant data across the globe.

- Extreme accuracy and reliability as the system would be used as point of reference

- A highly customized application for business KPIs along with an open platform that provides the ability to easily integrate with IT systems

The Solution

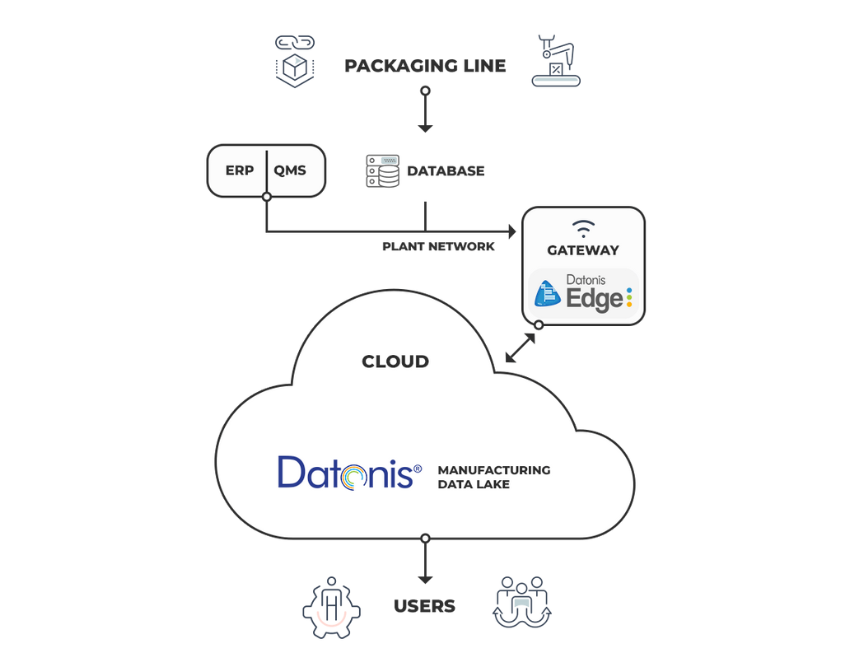

- Datonis Edge: It is a distributed computing platform that allows Industrial IoT data to be processed closer to the edge of the network.

- IoT: It makes for the repository for storing and processing all machine and manufacturing data, and is the data lake for the implementation.

- Datonis Digital Factory: This unified digital manufacturing platform is powered by IoT and comes with out-of-the box apps for monitoring, measuring, analyzing and predicting outcomes using AI.

Benefits

Productivity Improvement

Get an insight into parameters that impact line productivity, such as line rates, loss, and quality analysis at multiple levels.

Machine Condition Monitoring

Monitor and analyze parameters that are critical to machine health. Optimize machine downtime by predicting failure before it occurs.

Manufacturing Data Lake

It is an open data platform that acts as a repository for all critical processes, to easily integrate IT systems with process data.

Consumables

Analyze energy and other consumables that are part of the production process and discover ways to optimize their utilization.

Plug and Play

Deploy and scale the hardware installation and the platform rapidly across geographies with zero downtime and minimal configuration.

Integrated Security

The platform is fully integrated with single-sign-on into the customer’s application suite providing seamless access.