HIL Limited Uncovers Productivity and Energy Optimization Opportunities With Datonis

Business Impact

- Significant increase in OEE within 2 months

- Real-time updates on bottlenecks and associated reasons

- Traceability began to yield results within 2 months

- A paperless shop-floor following the digitization of paper logbooks

- Accurate and real-time assessment of energy usage

Our Role

- Connecting 4 plants in a scalable manner, with emphasis on digitally mapping the entire shop floor

The Problem

HIL Could Foresee the Need for a Digital Road Map for Connecting 20 Plants

Established in 1946, HIL Limited is a flagship company of the $2.4 Billion conglomerate, CK Birla Group. The company offers comprehensive building materials and solutions since last 70 years and manufactures asbestos cement sheets (roofing), AAC blocks (walling), and CPVC, UPVC and column pipes (polymer solutions).

HIL, being a 70 year old organization, had close to 20 manufacturing plants, each commissioned at different years. This came with different maturity levels and different problem statements. The team was keen to optimize productivity and identify opportunities for cost and energy saving. Their main concern was the lack of real-time visibility into process data, which was leading to quality issues. Moreover, they weren’t able to assess the energy expenditure across all the processes and equipment. The data was being captured on paper logbooks. Even if the data from PLC/SCADA was available, only the operators had access. That made it difficult for the team make any real-time process connections. They were also struggling with the lack of a real-time warning system for proactive and predictive process management.

In their first step to digital transformation, HIL was looking at:

- Productivity Optimization

- Energy Expenditure

- Quality Improvement

- Batch-Level Traceability

“We were definitely not looking at only one production line or one use case such as asset monitoring. We were always looking at a foundational layer that can lay the path per Industry 4.0.

For example, if you have connected shop floor for the entire plant, then you can address all aspects of the plant operation whether it is your OEE improvement or efficiency improvements, asset monitoring or condition based monitoring to ensure the quality is predicted and delivered. Or you can look at data analytics for predictive maintenance or raw material consumption. In either of these cases, you can assess how to finetune your process.

There are many use cases in Industry 4.0 but an Industrial IoT platform can bring it all together to ensure real-time decision making. So that’s how we started our journey, by laying out the connected shop floor.”

The Solution

As part of the ‘Connected Shopfloor’ project, Altizon’s Datonis suite was deployed at HIL across 4 locations for optimizing Productivity, CBM, Quality and Energy.

The solution targeted 4 Strategic Business Units (SBUs), each dealing with a different product and manufacturing process:

- Two plants: Cement Sheets

- Cement Blocks

- Pipes

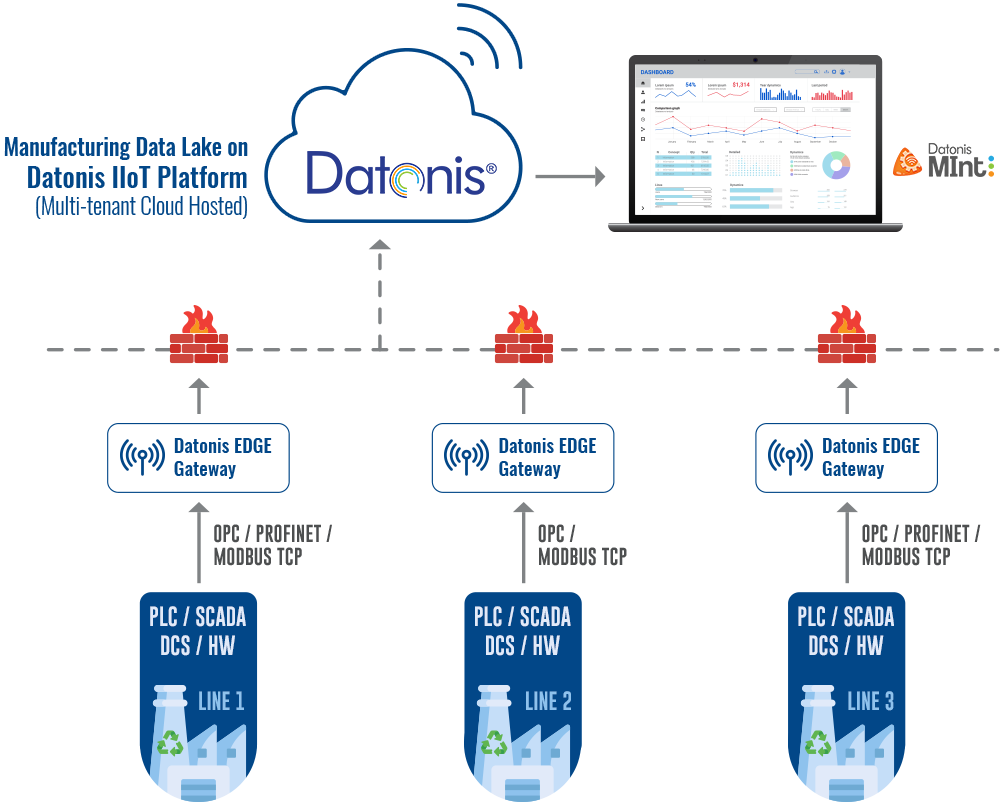

The HIL team leveraged Datonis Edge for data acquisition from PLC/SCADA and built a manufacturing data lake on multi-tenant cloud. They also made use of various modules for real-time analytics and dashboarding.

Use Cases

Correct Performance Measurements

A connected shop-floor helps with timely availability and accuracy of data, enabling the plant operations team to take corrective actions in real-time.

Digital Dashboards

Digital dashboards provide real-time insights to the plant head into key KPIs across Productivity, Quality, Maintenance and Energy dimensions.

Energy

The production team can analyze the energy usage across all processes and keep the expenditure in check.

Process Deviation Alerts

Operators and (or) supervisors get alerts to act upon any process deviation with continuous monitoring of critical process parameters.

Batch Traceability

Production teams are able to respond quickly to issues by tracing back a part or product through the supply chain to identify the root cause.

Explore Other Case Studies

SRF Connects a Complex Chemical Manufacturing Process and Drives Improvements in Product Quality

JK Tyre Achieves Continuous Process Quality Optimization and Condition Monitoring With Datonis

TVS Motor Company Gears Up for Industry 4.0 Using Datonis and Benefits From Horizontal Deployment

Visibility Equals Accountability

Pick a manufacturing line of your choice and let Altizon digitally transform it within 4 weeks.