OPC: Basics, History and Necessity

The manufacturing sector, unlike other verticals, prefers to rely on time-tested solutions rather than embracing everything that is new in technology. A few years ago, IoT was a buzzword or a proof of concept usually reserved for the amusement of R&D team. Fast forward to today, the scenario has changed and IoT has proved itself in providing clear RoI benefits.

The strength of an IoT infrastructure is based on how well the systems communicate with each other on a plant-wide basis to exchange data/information securely and reliably. OPC is one of the most widely used standards for this.

What is OPC?

OPC is a series of standards and specifications for Industrial Automation Industry. It specifies a protocol for real-time communication within a plant having different control devices from different manufacturers. OPC which now refers to Open Platform Communications was originally termed as Object Linking and Embedding for Process Control.

OPC, which is based on OLE, COM, DCOM technology, is designed as a bridge for Windows-based application and process control hardware.

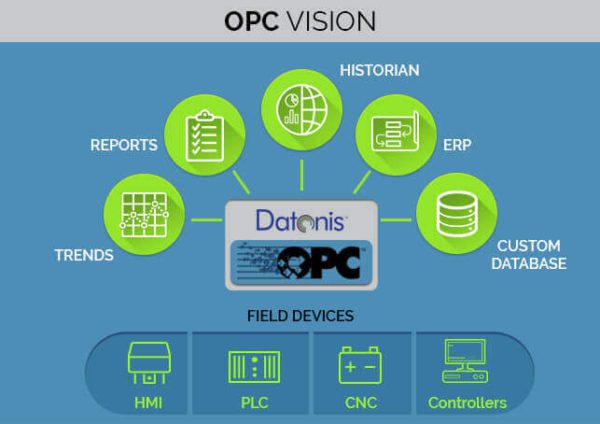

OPC (Open Platform Communications) Vision for the Internet of Things in Manufacturing

History and Necessity of OPC

Before OPC came into the picture, each OEM vendor had applications using its own drivers and was storing data in proprietary data paths. This created a multitude of problems for manufacturers since every vendor created their own information silos and ultimately they were not able to use this data for creating reports. They had to create custom solutions from these different vendors for creating reports. There was little integration possible since data was locked in a proprietary format. Data was locked in different PLC models, HMIs, CNC machines and ERPs. Also, the plants would face the challenge of change management whenever a new system was added.

OPC was introduced as a solution to solve these issues rather than creating a new product to standardize technology with no proprietary format and to facilitate universal connectivity.

OPC in IoT

A significant advancement in OPC development like OPC Unified Architecture makes it platform independent, thus allowing it to be embedded into devices & making it ideal for IoT use cases. One of the value propositions of OPC UA is scalability from Sensor to Cloud. This also allows IoT players to model data based on specific domains as MT connect and BACnet.

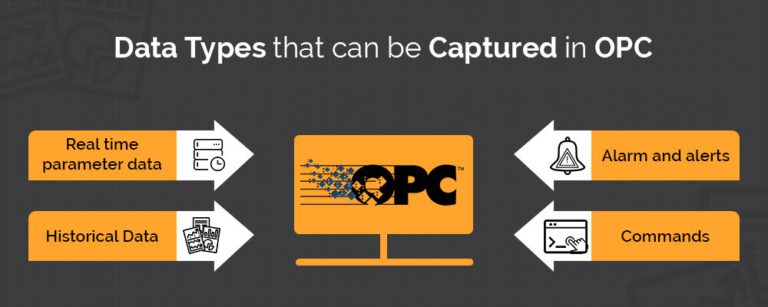

Following are the data types that can be captured in OPC

- Real-Time Parameter Data

- Historical Data

- Alarm and Alerts

- Commands

Apart from being a common pool for streaming data to cloud app or a third-party app, OPC is also the backbone of any SCADA system wherein a change in a tag value or command triggers change in the status of connected machines.

How Altizon Uses OPC in IoT

Altizon, an innovator in the Industrial Internet of Things space, leverages OPC with IoT to enable productivity & OEE for manufacturers. Altizon utilizes the power of OPC through different OEM hardware with integrated OPC UA/DA embedded into them.

A typical installation involves collecting data from PLC, Sensors, CNC controllers, Relays, HMIs and CSVs using different IoT standards and protocols and bringing them to a common hardware platform, which then pushes data into OPC.

Altizon has developed an Agent / Client that captures the data stored in OPC tag and sends it in real time to its IoT cloud platform Datonis. All device and API communication is over TLS 1.2. The data is encrypted using 256 bit AES with Cloud out-of-the-box support for REST API, MQTT- ISO/IEC Standard (for Remote Monitoring).

While OPC and IoT work behind the scene, for customers the business outcome with these is in the form of deep insights around productivity, OEE and quality.

In simple terms, OPC plays the role of a postman between controllers and Edge installed on a PC, leveraging UA or Modbus protocol.

- Learn how a Global Metal Forging Company Laid the Foundation for Industry 4.0 Using Datonis

- Download Datonis Brochure

- Connect with an Altizon representative to learn more about our offerings