IoT and SCADA: Complementary Technologies for Industry 4.0

The last few years have seen the emergence of two initiatives that promise to usher in a new era for manufacturing. The first is Industry 4.0 vision that outlines the next generation Smart Connected Factory. The second is Internet of Things (IoT), a network of physical devices or ‘things’ that are interconnected and can exchange information about their operation and about the environment in which they function.

Manufacturing is a mature industry with machines and assembly lines that run with a high degree of automation. Supervisory Control & Data Acquisition Systems (SCADA) and Distributed Control Systems (DCS) are prevalent industry standards. So how is IoT relevant to manufacturing and how is it a critical part of your Industry 4.0 initiative?

IoT is complementary to SCADA and DCS. Information generated from SCADA systems acts as one of the data sources for IoT. SCADA’s focus is on monitoring and control. IoT’s focus is firmly on analyzing machine data to improve productivity and impact the top line.

Scada systems consist of:

- Programmable Logic Controllers (PLCs) and Remote Terminal Units (RTUs): These are hardware components that interface with the machines and control them. They are responsible for interfacing with sensors in the machines. All parameters that require monitoring are available here. PLCs and RTUs are your interfaces to the machine world.

- Data Acquisition Systems: These are centralized systems that collect data from PLCs and RTUs. The connectivity could be wired (Modbus, TCP) or wireless. OPC (OLE for Process Control) is a recommended way to connect to your hardware.

- Supervisory Systems: These are systems that allow supervisors to monitor their machines. These systems do real-time condition monitoring, raise alarms when thresholds are breached and ensure that your machinery works optimally.

SCADA systems work perfectly for supervisors and are ideal for day-to-day monitoring of what is going on in your factory. IoT solutions come in when you have more macro level questions to ask. Questions like:

- What is my operational effectiveness across machines, assembly lines and plants? What can I do to improve it?

- What are my bottlenecks? How can I eliminate them?

- What process changes can I do to improve performance?

- How can I do a planned vs actual comparison?

- Can I predict machine failure? How can I move from calendar-based maintenance to predictive maintenance?

These questions are extremely relevant to plant managers, production supervisors, capacity planning personnel and productivity consultants. IoT in manufacturing is meant for this audience.

The Internet of Things:

The Internet of Things is a culmination of advances in connectivity hardware, data networks, cloud computing and big-data processing. IoT begins where the work on SCADA, DCS and Historians end.

A typical factory is an extremely heterogeneous environment that has grown organically over several years and in some cases over decades. Some of the challenges faced by factories are:

- Machines with different kinds of PLCs and RTUs that support different connectivity protocols

- Multiple SCADA systems from different vendors, each controlling a specific line or a set of lines

- The presence of data islands, with SCADA systems only able to store a finite amount of data, leading to the absence of historical data for deeper analysis

- Legacy machines that are not connected as they lack the right kind of instrumentation

- Assets as energy meters that have never been connected due to cost overheads but hold vital information

- Existing data Historians can be a data source

IoT platforms act as a federated data store of all these diverse data sets. They give you a single source of truth for your machine data.

However, what does an IoT platform consist of?

IoT Platforms Explained

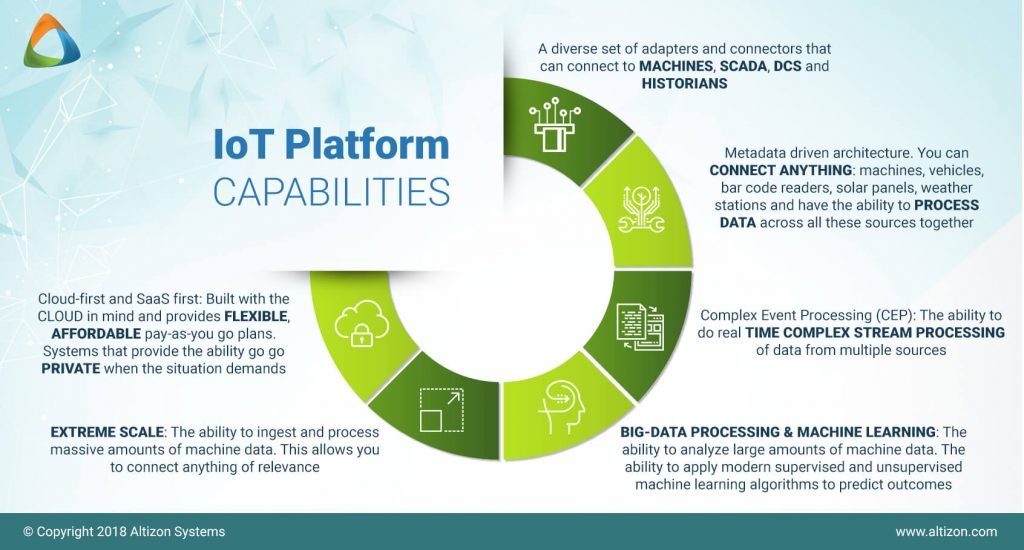

Internet of Things (IoT) Platform Capabilities Explained

IoT platforms have the following capabilities:

- A diverse set of adapters and connectors that can connect to machines, SCADA, DCS, and Historians

- Metadata driven architecture, which essentially means you can connect anything: machines, vehicles, barcode readers, solar panels, weather stations and have the ability to process data across all these sources together

- Complex Event Processing (CEP) or the ability to do real-time complex stream processing of data from multiple sources

- Big-data processing and machine learning to analyze large amounts of machine data

- The ability to ingest and process massive amounts of machine data

- Cloud-first and SaaS-first platforms provide flexible, affordable pay-as-you go plans

As IoT gains focus and traction, many existing SCADA systems and Historians are providing IoT like features. However, they can never replicate the capabilities of a platform, purpose built from the ground up with IoT in mind. Do keep this in mind as you begin your IoT journey.

Next Steps

This article has hopefully given you a perspective on how IoT is relevant to your business and can be your stepping stone to Industry 4.0. Get started by connecting a couple of your assembly lines to a modern IoT platform and seeing how machine data analytics can really impact your business. Click here to create a free account for Datonis and experience the power of IoT for your devices.

Altizon is focused on helping you get started with the Industrial Internet of Things and Industry 4.0. We provide adapters to connect existing hardware, SCADA, DCS and Enterprise Data Historians. Altizon’s Datonis platform is a highly scalable, cloud-based IoT platform that allows devices to securely connect and exchange information in real-time.

Manufacturers are increasingly adopting industrial IoT platforms to transform their enterprise into a smart factory with scalable technology. Let Altizon connect one of your key processes within 4 weeks and uncover opportunities for payback.